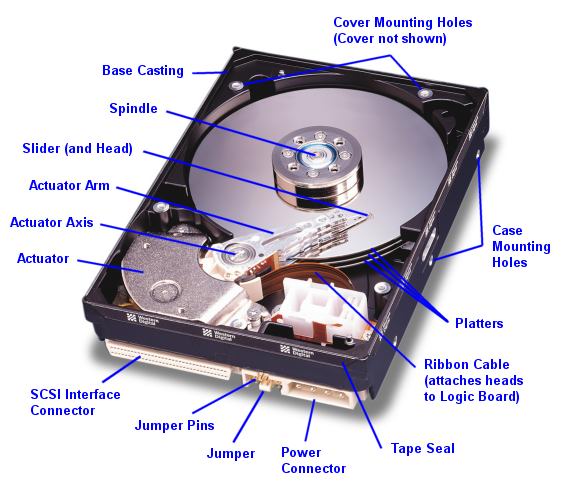

A hard disk drive is a persistent storage device that stores and retrieves data using rapidly rotating disks (platters) coated with magnetic material. The key components of a hard disk drive (HDD) are platter, spindle, read-write head, actuator arm assembly, and controller board.

I/O operations in an HDD are performed by rapidly moving the arm across the rotating flat platters coated with magnetic material. Data is transferred between the disk controller and magnetic platters through the read-write (R/W) head which is attached to the arm. Data can be recorded and erased on magnetic platters any number of times.

Hard Disk Drive (HDD) Strucutre

Data on the disk is recorded on tracks, which are concentric rings on the platter around the spindle. Each track is divided into smaller units called sectors. A sector is the smallest, individually addressable unit of storage.

The track and sector structure is written on the platter by the drive manufacturer using a low-level formatting operation. The number of sectors per track varies according to the drive type. There can be thousands of tracks on a platter, depending on the physical dimensions and the recording density of the platter.

Also Read: Server-Storage Architecture Overview

Typically, a sector holds 512 bytes of user data; although some disks can be formatted with larger sector sizes. In addition to user data, a sector also stores other information, such as the sector number, head number or platter number, and track number. This information helps the controller to locate the data on the drive.

The track and sector structure is written on the platter by the drive manufacturer using a low-level formatting operation. The number of sectors per track varies according to the drive type. There can be thousands of tracks on a platter, depending on the physical dimensions and the recording density of the platter.

Also Read: Server-Storage Architecture Overview

Typically, a sector holds 512 bytes of user data; although some disks can be formatted with larger sector sizes. In addition to user data, a sector also stores other information, such as the sector number, head number or platter number, and track number. This information helps the controller to locate the data on the drive.

Platter: A typical HDD consists of one or more flat circular disks called platters. The data is recorded on these platters in binary codes (0s and 1s). The set of rotating platters is sealed in a case, called Head Disk Assembly (HDA). A platter is a rigid, round disk coated with magnetic material on both surfaces (top and bottom). The data is encoded by polarizing the magnetic area or domains of the disk surface. Data can be written to or read from both surfaces of the platter. The number of platters and the storage capacity of each platter determine the total capacity of the drive.

Spindle: A spindle connects all the platters and is connected to a motor. The motor of the spindle rotates with a constant speed. The disk platter spins at a speed of several thousands of revolutions per minute (rpm). Common spindle speeds are 5,400 rpm, 7,200 rpm, 10,000 rpm, and 15,000 rpm. The speed of the platter increases with the improvement in technology; although the extent to which it can be improved is limited.

Also Read: The next generation IT Data Center Layers

Also Read: The next generation IT Data Center Layers

Read/Write Head: This component will read and write data from or to the platters. Drives have two R/W heads per platter, one for each surface of the platter. The R/W head changes the magnetic polarization on the surface of the platter when writing data. While reading data, the head detects the magnetic polarization on the surface of the platter. During reads and writes, the R/W head senses the magnetic polarization and never touches the surface of the platter. When the spindle rotates, a microscopic air gap is maintained between the R/W heads and the platters, known as the head flying height. This air gap is removed when the spindle stops rotating and the R/W head rests on a special area on the platter near the spindle. This area is called the landing zone. The landing zone is coated with a lubricant to reduce friction between the head and the platter. The logic on the disk drive ensures that heads are moved to the landing zone before they touch the surface. If the drive malfunctions and the R/W head accidentally touches the surface of the platter outside the landing zone, a head crash occurs. In a head crash, the magnetic coating on the platter is scratched and may cause damage to the R/W head. A head crash generally results in data loss.

Actuator arm assembly: R/W heads are mounted on the actuator arm assembly, which positions the R/W head at the location on the platter where the data needs to be written or read. The R/W heads for all platters on a drive are attached to one actuator arm assembly and move across the platters simultaneously.

Drive controller board: The controller is a printed circuit board, mounted at the bottom of a disk drive. It consists of a microprocessor, internal memory, circuitry, and firmware. The firmware controls the power supplied to the spindle motor as well as controls the speed of the motor. It also manages the communication between the drive and the compute system. In addition, it controls the R/W operations by moving the actuator arm and switching between different R/W heads, and performs the optimization of data access.

Logical Block Addressing (LBA)

The earlier drives used physical addresses consisting of cylinder, head, and sector (CHS) number to refer to specific locations on the disk, and the OS had to be aware of the geometry of each disk used. Logical block addressing (LBA) has simplified the addressing by using a linear address to access physical blocks of data. The disk controller translates LBA to a CHS address, and the servers needs to know only the size of the disk drive in terms of the number of blocks. The logical blocks are mapped to physical sectors on a 1:1 basis.

Performance of an Hard Disk Drive

A disk drive is an electromechanical device that governs the overall performance of the storage system environment. Determining storage requirements for an application begins with determining the required storage capacity and I/O performance.

Capacity can be easily estimated by the size and number of file systems and database components used by applications. The I/O size, I/O characteristics, and the number of I/Os generated by the application at peak workload are other factors that affect performance, I/O response time and design of storage system.The various factors that affect the performance of disk drives are

Also Read: Types of RAID Levels

Also Read: Types of RAID Levels

Seek Time: The seek time (also called access time) describes the time taken to position the R/W heads across the platter moving along the radius of the platter. In other words, it is the time taken to position and settle the arm and the head over the correct track. Therefore, the lower the seek time, the faster the I/O operation. Each of these specifications is measured in milliseconds (ms). The seek time of a disk is typically specified by the drive manufacturer. Seek time has more impact on the I/O operation of random tracks rather than the adjacent tracks.

Rotational Latency: To access data, the actuator arm moves the R/W head over the platter to a particular track while the platter spins to position the requested sector under the R/W head. The time taken by the platter to rotate and position the data under the R/W head is called rotational latency. This latency depends on the rotation speed of the spindle and is measured in milliseconds. The average rotational latency is one-half of the time taken for a full rotation. Similar to the seek time, rotational latency has more impact on the reading/writing of random sectors on the disk than on the same operations on adjacent sectors.

Data Transfer Rate: The data transfer rate also called transfer rate refers to the average amount of data per unit time that the drive can deliver to the HBA. In a read operation, the data first moves from disk platters to R/W heads; then it moves to the drive’s internal buffer. Finally, data moves from the buffer through the interface to the compute system’s HBA. In a write operation, the data moves from the HBA to the internal buffer of the disk drive through the drive’s interface. The data then moves from the buffer to the R/W heads. Finally, it moves from the R/W heads to the platters. The data transfer rates during the R/W operations are measured in terms of internal and external transfer rates. Internal transfer rate is the speed at which data moves from a platter’s surface to the internal buffer (cache) of the disk. The internal transfer rate takes into account factors such as the seek time and rotational latency. External transfer rate is the rate at which data can move through the interface to the HBA.

Disk I/O Controller

The utilization of a disk I/O controller has a significant impact on the I/O response time. The I/O requests arrive at the controller at the rate generated by the application. The I/O arrival rate, the queue length, and the time taken by the I/O controller to process each request determines the I/O response time. If the controller is busy or heavily utilized, the queue size will be large and the response time will be high.

As the utilization reaches 100 percent, that is, as the I/O controller saturates, the response time moves closer to infinity. In essence, the saturated component or the bottleneck forces the serialization of I/O requests; meaning, each I/O request must wait for the completion of the I/O requests that preceded it. When the average queue sizes are low, the response time remains low. The response time increases slowly with added load on the queue and increases exponentially when the utilization exceeds 70 percent. Therefore, for performance-sensitive applications, it is common to utilize disks below their 70 percent of I/O serving capability.

Next: Solid State Drive (SSD) Overview

Go To >> Index Page

What Others are Reading Now...

0 Comment to "2.2 ElectroMechanical Hard Disk Drive (HDD) Overview"

Post a Comment